In the factory building of Taizhong Group's new energy forklift production base, large and small forklifts are neatly arranged. Although they have different sizes, they all have a common color - green. As the largest new energy intelligent forklift manufacturing base in a single factory in the world, it produces lithium-ion, hydrogen, methanol and other clean-powered forklifts. New energy forklifts of different tonnages meet the needs of various scenarios.

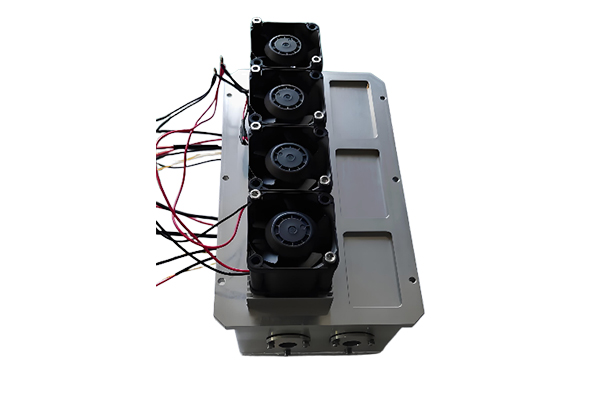

At the launch site on the same day, the most eye-catching C position was a 65-ton forklift, which is currently the world's largest lithium-ion counterbalanced forklift. "This forklift can carry up to 65 tons, which is equivalent to lifting dozens of family cars at one time! The strong power comes from the 528kWh lithium battery pack, and the double-gun fast charge can be fully revived in 1.5 hours. Due to the use of lithium batteries, its carbon emissions are zero," Zhao Pengxin, technical specialist of Taizhong Group, told reporters. This "Big Mac" can provide strong lifting capacity and precise micro-motion control in ports, steel enterprises, and large-scale infrastructure projects. "It represents the highest level of electrification of heavy-duty handling," Zhao Pengxin said.

In this new energy intelligent forklift manufacturing base, a green power matrix of "lithium battery + hydrogen fuel + methanol" is created, with the ability to produce 100,000 new energy forklifts per year. Forklift manufacturing is intelligent in the whole process from machining, welding, painting to assembly and testing. It only takes 6.5 minutes from a steel plate to a forklift off the assembly line. Redefine handling with technology to stimulate the surging power of green energy.

English

English 繁体中文

繁体中文 简体中文

简体中文 Deutsch

Deutsch